Laser Shaft Alignment Services

Precision Maintenance with Laser shaft alignment.

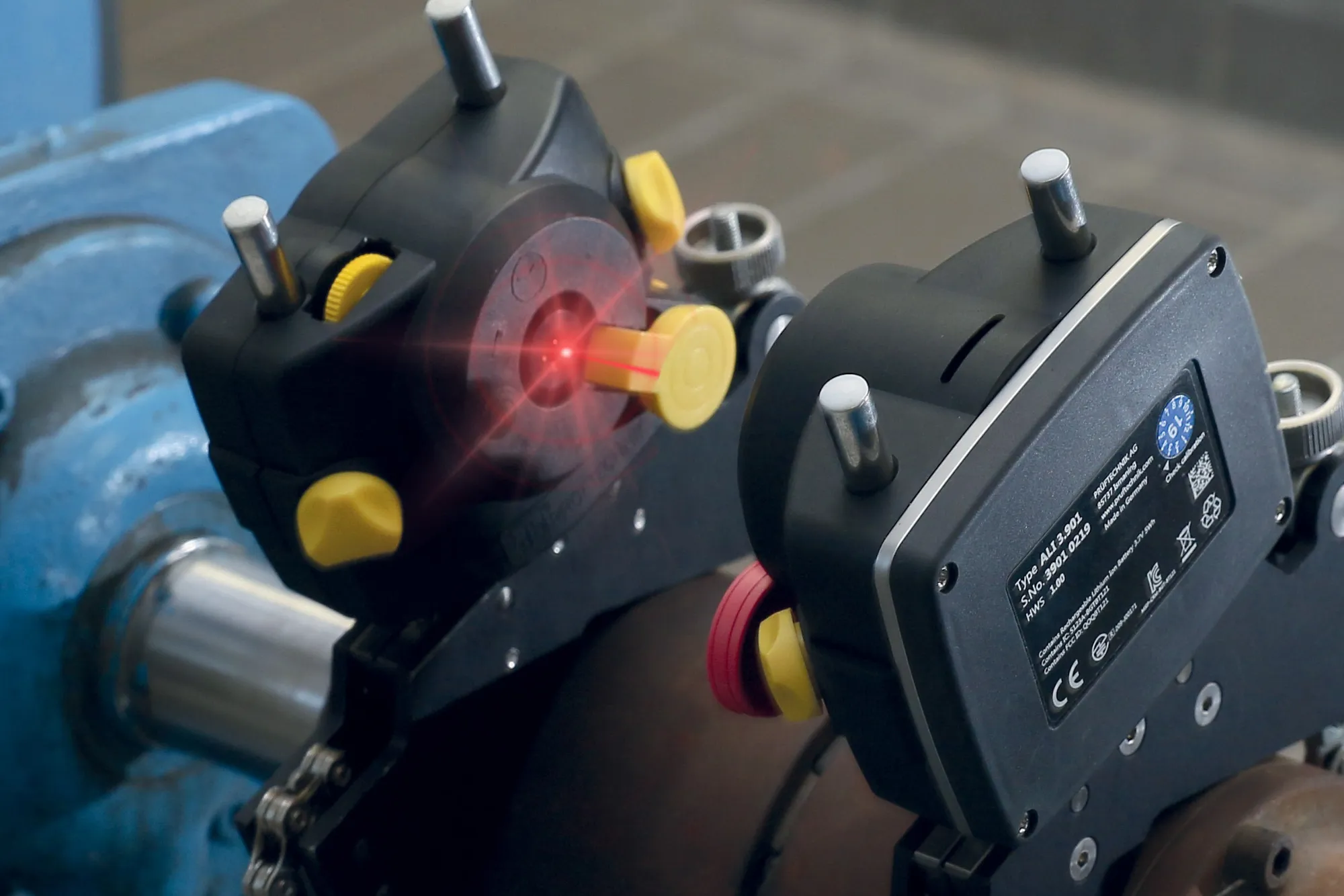

Laser shaft alignment is a critical process in a condition monitoring system that utilises the high-accuracy laser measurement to align the rotational axes of coupled machinery. By fixing angular and offset misalignment, this process ensures machine reliability.

What is laser shaft alignment?

Shaft alignment is a specialised method to precisely position the rotational centers or the axes of two or more coupled shafts so they remain colinear during routine working conditions. This meticulous process involves carefully minimising the angular as well as offset misalignment across both horizontal and vertical levels. These misalignments can arise due to various reasons such as thermal expansion, installation or manufacturing errors, base shifts, and they can cause disruptive vibrations, excess noises, early bearing or seal wear, and fatigue to the equipment. The advanced shaft alignment employs laser-based tools to detect even the smallest deviation in shaft position with high precision. This allows for taking corrective fixes efficiently and accurately.

At AssetConditionMonitoring, we provide top-quality laser shaft alignment tools and services using the latest technology. We help you accurately detect even the smallest misalignments in real-time. Our experienced engineers carefully consider factors like thermal expansion and dynamic loads, and address the concerns with utmost effectiveness. We ensure your equipment runs efficiently, with reduced wear and prolonged operational life.

Related services

Our Proven Procedure for Precision Laser Shaft Alignment

Pre-alignment Set-up

At first, our technicians gather the relevant details such as the machinery type, specifications, thermal growth measurements, alignment tolerances, past issues, etc., followed by a quick visual inspection. We then securely set the laser alignment system by mounting the laser transmitter on a shaft and the receiver on the counter shaft using fixtures such as brackets or magnetic bases.

Initial Data Collection

Using laser alignment tools, the existing misalignment in shafts is measured. The transmitter and receiver give precise shaft positions. The baseline measurements of misalignment in the horizontal and vertical planes are taken to decide on the next step. As the system detects deviations in the laser path, precise data on angular and offset misalignment is received in real-time.

Laser Alignment

Using the precise measurement received from laser systems, technicians carefully adjust the machinery shafts by repositioning the machinery, using shims, adjusting foundation bolts, or realigning the coupling to eliminate angular and offset deviations. The misalignment is minimised at this stage, and optimal shaft alignment is achieved within the specified tolerances. Perform a final measurement cycle to confirm that the alignment meets specified tolerances and document the results for quality assurance.

Laser Alignment

Using the precise measurement received from laser systems, technicians carefully adjust the machinery shafts by repositioning the machinery, using shims, adjusting foundation bolts, or realigning the coupling to eliminate angular and offset deviations. The misalignment is minimised at this stage, and optimal shaft alignment is achieved within the specified tolerances. Perform a final measurement cycle to confirm that the alignment meets specified tolerances and document the results for quality assurance.

Verify Realignment

After making the necessary adjustments, our technicians do a final measurement using the same laser alignment system to verify and confirm that the realignment meets the specified tolerances. This crucial step ensures the accuracy of the corrections and confirms that the shafts are properly aligned, guaranteeing optimal machine performance and reliability.

Reporting and documentation

Once the alignment is confirmed, a cumulative report is produced that documents the entire process, from initial measurements to the final results. This documentation acts as a valuable reference for future maintenance schedules, quality control, and auditing purposes.

Benefits of Laser shaft alignment

High precision

Laser alignment systems detect misalignment with high accuracy, ensuring precise shaft positioning for critical assets.

Efficient and effective

The laser alignment process is much faster than the conventional methods, with real-time measurements and easy adjustments, reducing downtime significantly.

Reduced component wear

Properly aligned shafts and shaft components reduce the vibration and mechanical fatigue, promoting the life of seals, bearings, and couplings.

Improved performance

Well-aligned shafts improve power transmission, leading to smoother and energy-efficient operation.

Reliable Laser alignment with assetconditionmonitoring.com

assetconditionmonitoring.com. is a leading expert in laser shaft alignment systems and laser shaft alignment services in the UAE and the Middle East. We provide high-precision laser alignment solutions employing the most modern laser technology to ensure reliable shaft alignment. Committed to excellence in condition monitoring, we have earned the trust of renowned industries across the region. Our skilled engineers conduct thorough inspections and on-site alignments, avoiding the need to relocate equipment and reducing downtime significantly. With a strong focus on precision and efficiency, our team ensures optimal machinery performance, helping clients enhance productivity and reduce operational costs.

Why Choose Us?

Expert Engineers

High-accuracy laser alignment system and tools

Cost-effective

On-site services

Reduced downtime

Frequently Asked Questions

The laser alignment cost can vary depending on factors like machine type, complexity, number of alignments, the equipment size, and on-site service requirements. For an accurate quote, it's best to seek a site-specific assessment.